Advantages Of Hydrocracking Reaction

Molecular Highway technology has broad applicability and value to the refining industry. Many refining processes utilize zeolite catalysts and additives. But the diffusion limits of these materials is a limiting factor, constraining reaction rates, yields, and ultimately refinery profitability. When applied to catalysts and additives in FCC, hydrocracking, alkylation, or dewaxing units, Molecular Highway technology creates a network of broad channels that allows feed molecules rapid access into and out of the active catalytic sites in the zeolite. The enhanced access – or improved diffusion – leads to better product yields and product quality and opens up new routes to profitability, such as processing more barrels or running heavier feeds.

A plain text display allows input of system operations and communicates boiler diagnostics. Buderus ecomatic 4000 schaltplan pdf free version. They can be fitted directly to the main control unit or wired to the boiler from the living or working space (as a room thermostat).

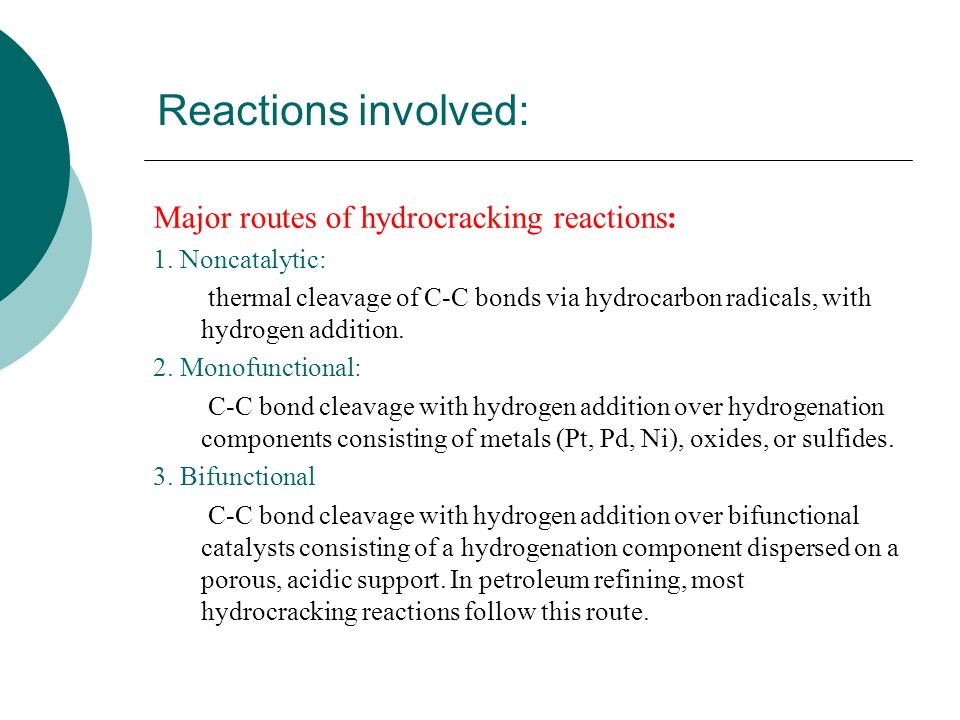

Hydrocracking Reactions Many simultaneous chemical reactions occur in hydrocracking. Mechanism of hydrocracking is that of catalytic cracking with hydrogenation superimposed. Catalytic cracking is the scission of a carbon–carbon single bond, and hydrogenation is the addition of hydrogen to a carbon–carbon double bond. Catalytic hydrocracking. These results were explained by the combination of a very high surface area (> 900 m 2 /g) and the presence of uniform pores in the mesopore range (ca. 3.0 nm), which facilitated the diffusion of large feed molecules, together with a mild acidity and high stability. Esercizi di solfeggio cantata pdf free pdf.

FCC FCC catalysts powered by Molecular Highway technology enable feed molecules, such as VGO, resid or hydrotreated feeds, enhanced access to and exit from the active catalytic sites in the zeolite. As a result, bulky feed molecules crack on the zeolite’s active sites, as opposed to on the less selective matrix material. And valuable cracked products, such as distillate, naphtha, and olefins, rapidly exit the zeolite cage before overcracking into undesirable byproducts like bottoms oil, coke and light gases. As a result, refiners using catalysts powered by Molecular Highway technology make more of what they want, and less of what they don’t. Refiners can take further advantage of the coke selectivity of Molecular Highway catalysts by running more barrels through the FCC and processing heavier feeds. Refiners using catalysts powered by Molecular Highway technology can expect increased margin in the range of $.75 – $3.00 per barrel of FCC feed. Benefits can be realized by simply switching catalysts.

FCC catalysts powered by Molecular Highway technology can be formulated and tailored for a specific refiner’s yield objectives, feed properties, and constraints. The key physical properties of catalysts powered by Molecular Highway– namely stability, attrition resistance, fluidization – are similar to that of conventional catalysts. Rive is, the world’s leading supplier of FCC catalysts. Molecular Highway FCC catalysts have been trialed successfully in two refineries in North America, and are currently available from Rive and W.R. For more information on the benefits of Molecular Highway technology in FCC, please download our summary: HYDROCRACKING Like the FCC process, Hydrocracking is a key process used in the refinery, enabling the efficient conversion of crude oil into desirable transportation fuels. As the worldwide demand for diesel fuel and high octane gasoline has grown, so too has the demand for hydrocracking catalysts. The enhanced accesses into and out of the zeolite provided by Rive’s Molecular Highway technology can overcome diffusional limits resulting in enhanced product yields of middle distillates.